Tanvi Munjal

Coveralls stand as one of the most iconic and enduring garments in both workwear and fashion history. From the industrial revolution workshops to contemporary runways, these distinctive garments have transcended their utilitarian origins to become cultural symbols of craftsmanship, durability, and authentic style. The global market for workwear, including coveralls, continues to expand rapidly as industries prioritize worker safety and consumer fashion trends increasingly embrace functional clothing.

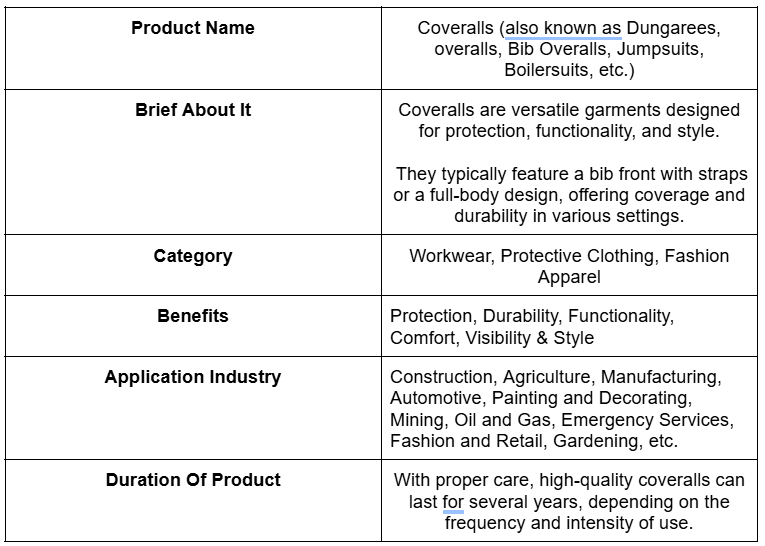

About Product

Types of Coveralls Include

- Overalls: Full-body protection, often used in industrial settings.

- Bib and Brace Overalls: Popular in agriculture and carpentry, featuring a bib with shoulder straps.

- Jumpsuits: Similar to coveralls but more tailored.

- Boilersuits: Used in environments with heat or steam.

- Dungarees: Known for casual style and comfort.

- Hi-Vis Overalls: For visibility in low-light conditions.

- Disposable Coveralls: Lightweight and breathable for temporary use.

- Specialized Overalls: Include flame-resistant, waterproof, and padded versions for specific industries.

Production Process of Coveralls

- Design and Pattern Making

- Design Concept: The process begins with creating a design concept that meets specific requirements, including fit, functionality, and style. Designers collaborate with industry experts to ensure the coveralls provide adequate protection and comfort.

- Pattern Creation: Technical designers transform the design concept into technical patterns, which serve as templates for cutting the fabric.

- Fabric Sourcing and Selection

- Fabric Selection: Suitable fabrics are chosen based on the design, functionality, and cost requirements. Common fabrics include cotton, polyester, and blends, each offering unique properties such as breathability, durability, or resistance to specific hazards.

- Fabric Testing: Selected fabrics undergo tests like colourfastness, shrinkage, and strength to ensure they meet quality standards.

- Cutting

- Spreading and Cutting: Fabric layers are spread out and aligned according to the marker, ensuring accurate cutting. The fabric is then cut along the outlines of the pattern pieces using cutting machines or manual tools.

- Bundling: Cut pieces are bundled and labelled for further processing.

- Sewing and Assembly

- Sewing: Skilled seamstresses or machines sew the cut pieces together, adding features such as pockets, zippers, and adjustable straps to enhance functionality.

- Assembly: The garment is assembled, and any additional components like buttons or buckles, are attached.

- Quality Control

- Inspection: Each garment is inspected for defects in stitching, fabric, and overall construction to ensure the high standards required for protective workwear.

- Adjustments: Any necessary adjustments are made to ensure the garment meets quality and safety standards.

- Finishing and Packaging

- Finishing Touches: Final touches include ironing, folding, and any additional treatments like washing or coating to achieve specific finishes.

- Packaging: The coveralls are packaged for distribution, ensuring they reach the customer in perfect condition.

Additional Steps for Specialized Coveralls

- Taping Seams: For coveralls intended for use in environments where fluid or aerosol protection is needed, seams are taped to prevent entry.

- Specialized Treatments: Fabrics may undergo specialized treatments to enhance properties such as flame resistance or chemical resistance.

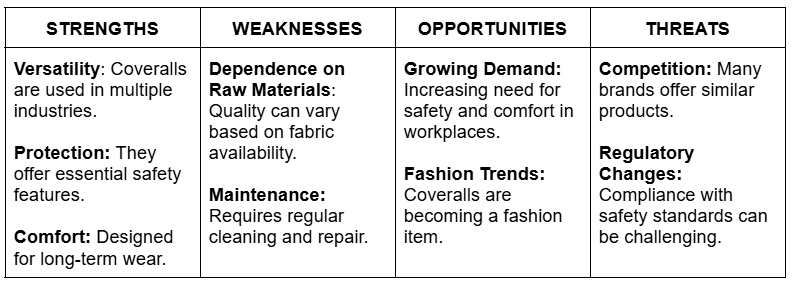

SWOT Analysis

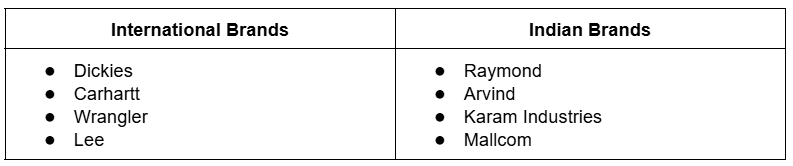

Major Brands

Conclusion

The production of coveralls represents a perfect intersection of functional design, material science, and manufacturing expertise. Whether serving as essential protective equipment in hazardous environments or as fashion statements on urban streets, coveralls continue to evolve while maintaining their fundamental purpose of providing coverage, protection, and utility. As workplace safety standards advance and fashion cycles continue, the coveralls industry remains positioned for continued innovation and growth, serving diverse markets with increasingly specialized and refined products.